15th Century Somerset Vernacular Cottage Roof Details

This cottage roof has been radio carbon dated to between 1405 and 1460.

To aid with the dating of similar properties here are some of the roof carpentry details.

Truss

The truss has a 50 degree pitch.

It is smoke blackened indicating a former open hall house.

Later, after the introduction of a fireplace the smoke blackening was over painted in white lime wash,

see purlin image.

The principal rafters, 280x130 are of elm, hence radio carbon dating as elm cannot be dendro dated.

The cranked collar is secured by mortice and tenons. The top is grooved and the underside of the principals are notched for staves which indicates an infill panel. As the truss is blackend on both sides of this infill panel must have been either a grille or a later wattle and daub panel.

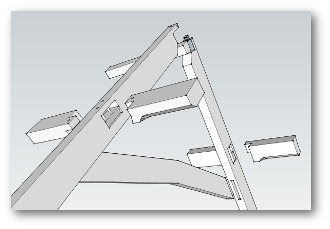

The sketch to the right can be view at a larger scale.

Purlins

There are two rows of inline butt purlins, with spurred soffits, one can be seen in the roof void.

The 250x140 purlins are chamfered with a run out see below left.

The purlins have open mortices, on the underside, with peg holes indicating former wind braces.

The purlins are set low, that is they are positioned one common rafter depth (80mm) below the top of the principal rafter. The top of the common rafter is at the same level as the top of the principal rafter (PR).

The purlin joints being in the middle of the PR is a much stronger detail than having trenched purlins so the depth of the PR can be reduced. This concept of design changes to save costly timber and reduce labour costs continues throughout the centuries. The low set purlin significant as it determines the ridge detail.

The empty housing for the purlin can be seen below right. This tapers to around 25mm deep at the bottom. The purlin has a "spurred soffit" which fits into this. The spur is the projection and the soffit is the underside. This detail supports the underside of the purlin and stops it sheering or splitting down its length, again allowing smaller sections of timber to be used.

The tenon of the opposing purlin can be seen top right of the housing. The 130mm depth of the principal rafter (PR)) is important here as it allows enough space for the length of the tenons, with the purlins in line. At later dates when PR's are shallower the purlins have to be offset or staggered to allow room for the tenons, which are typically 90-100mm long.

Ridge

The principal rafters meet with a vertical joint at the ridge.

This is a sensible detail as it reduces the risk of rot by avoiding exposed end grain.

The original 120x120 ridge, now missing, was diagonally set. This was set low, clasped, to match the purlins.

The top face being 80mm below the top of the PR. (PR top obscured by common rafters)

The low ridge results in the pegged PR joint moving from the more usual location below the ridge, to above it.

Saw marks

The faint diagonal line across the PR is a saw cut line. When the PR was cut, it was not in a saw pit, one end was raised on a trestle. The carpenter cut to the mid point, when he was getting too close to the floor he turned the timber round, leaving this cut mark.